Tekniska parametrar om PCB och PCBA

| Föremål | Kapacitet |

|---|---|

| Kvalitetsstandard | Standard IPC 2 |

| Skikt | 1-32 skikt |

| Råmaterial | ▪FR4 ▪CEM3 ▪Rogers ▪Teflon ▪Metallbaserad |

| Max storlek | ▪850mm*520mm |

| Min borrdiameter | 0,15 mm |

| Koppartjocklek | 0,25OZ-15OZ |

| Tolerans för impedans | ±5% |

| Ytfinish | ▪Kabelfri HASL ▪OSP ▪ENIG ▪Guldplätering ▪Immersion Ag/Sn |

| Föremål | Kapacitet |

|---|---|

| Kvalitetsstandard | IPC-610-C |

| Monteringsteknik | ▪SMT Stencil ▪SMT ▪DIP ▪Conformal Coating |

| Företagscertifiering | ▪ISO9001 ▪IATF16949 ▪ISO13485 ISO14001 |

| Produktcertifiering | ▪UL ▪RoHS ▪SGS ▪REACH |

| SMD-kapacitet | Minsta storlek:01005 ▪BGA0,2mm, QFN, CSP, CON ▪ Maximal PCB:510*460mm |

| Funktioner med mervärde | ▪Komponentupphandling ▪NPI-rapport ▪PCBA-prototyp ▪IC-programmering ▪Reparation |

| Testprocess | ▪AOI ▪Röntgen ▪SPI ▪FAI ▪FCT ▪ICT ▪Aging test ▪QC Manuell detektering |

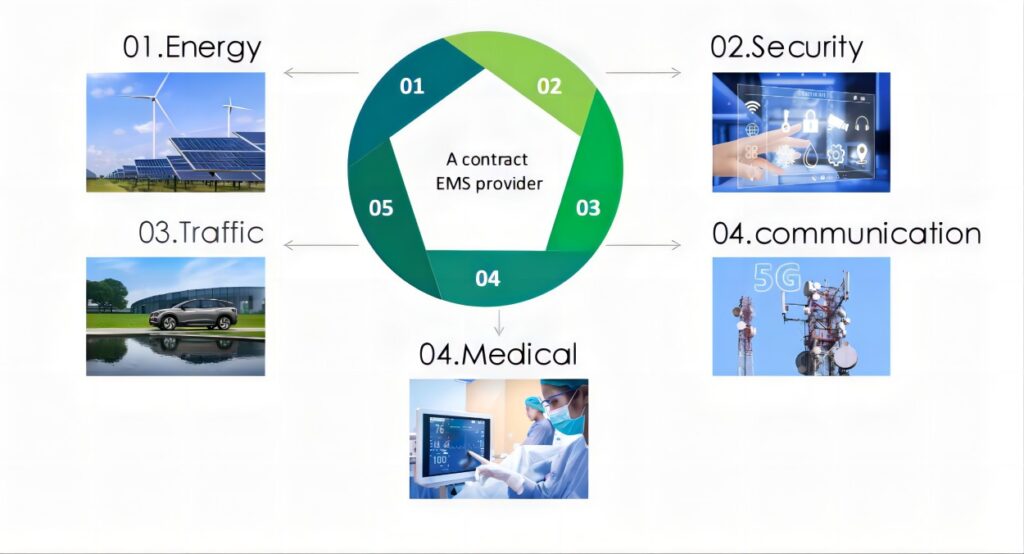

Användningsområden för PCBA

Specifika tillämpningar av PCBA

Säkerhet System

Kommunikation Enhet

Förarlös System

Nytt energisystem

Medicinteknisk utrustning

Vanliga frågor om PCB- och PCBA-applikationer

1. Vilka branscher använder PCBA-applikationer?

PCBA-applikationer omfattar konsumentelektronik, fordons- och flygindustrin, medicintekniska produkter, telekommunikation och industriell automation.

2. Vilka är de viktigaste komponenterna som används i PCBA?

Viktiga komponenter är resistorer, kondensatorer, dioder, transistorer, integrerade kretsar (IC), kontakter och induktorer.

3. Vilka testmetoder används för PCBA?

Vanliga testmetoder är ICT (In-Circuit Testing), FCT (Functional Testing), AOI (Automated Optical Inspection) och röntgeninspektion.

4. Vilka är utmaningarna inom PCBA-tillverkning?

Utmaningarna är bland annat att säkerställa lödfogens tillförlitlighet, hantera hög komponenttäthet, minimera elektromagnetisk interferens (EMI) och uppnå exakt komponentplacering.