Tehnični parametri o PCB in PCBA

| Artikel | Sposobnost |

|---|---|

| Standard kakovosti | Standard IPC 2 |

| Sloje | 1-32 plasti |

| Surovine | ▪FR4 ▪CEM3 ▪Rogers ▪Teflon ▪Kovinska osnova |

| Največja velikost | ▪850mm*520mm |

| Min premer vrtanja | 0,15 mm |

| Debelina bakra | 0,25OZ-15OZ |

| Toleranca impedance | ±5% |

| Površinska obdelava | ▪Brez svinca HASL ▪OSP ▪ENIG ▪Zlata obloga ▪Imersija Ag/Sn |

| Artikel | Sposobnost |

|---|---|

| Standard kakovosti | IPC-610-C |

| Tehnologija sestavljanja | ▪SMT šablona ▪SMT ▪DIP ▪Konformna prevleka |

| Certificiranje podjetij | ▪ISO9001 ▪IATF16949 ▪ISO13485 ISO14001 |

| Certificiranje izdelkov | ▪UL ▪RoHS ▪SGS ▪REACH |

| Zmogljivost SMD | ▪Minimalna velikost: 01005 ▪BGA0,2 mm, QFN, CSP, CON ▪Največja velikost PCB: 510 * 460 mm |

| Funkcije z dodano vrednostjo | ▪Naročanje komponent ▪NPI poročilo ▪PCBA prototip ▪IC programiranje ▪Popravilo |

| Postopek testiranja | ▪AOI ▪X-ray ▪SPI ▪FAI ▪FCT ▪ICT ▪Test staranja ▪QC Ročno odkrivanje |

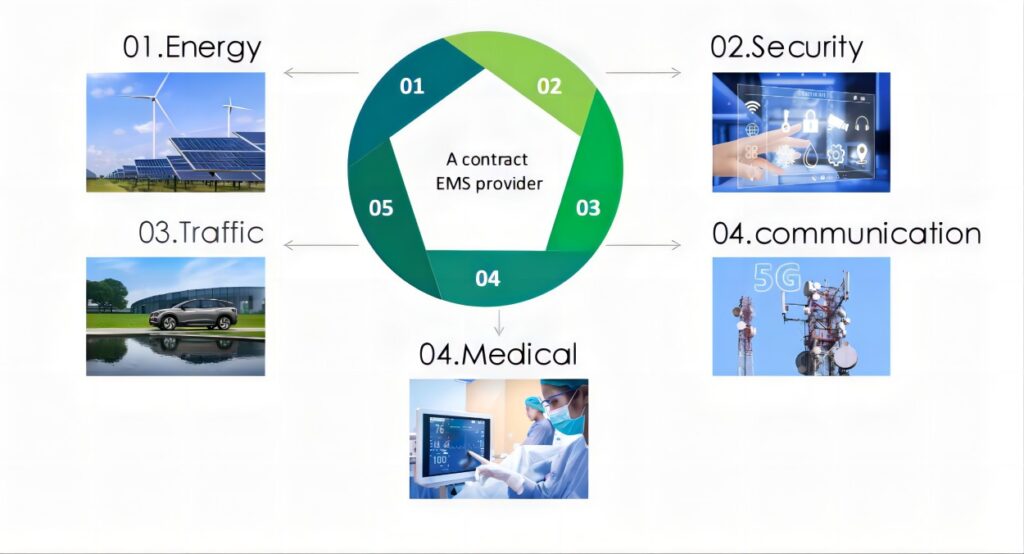

Področja uporabe PCBA

Posebne aplikacije PCBA

Varnost Sistem

Komunikacija Naprava

Brez voznika Sistem

Nov energetski sistem

Medicinski pripomoček

Pogosta vprašanja o aplikacijah PCB in PCBA

1. V katerih panogah se uporabljajo aplikacije PCBA?

PCBA se uporabljajo v potrošniški elektroniki, avtomobilski industriji, letalski in vesoljski industriji, medicinskih napravah, telekomunikacijah in industrijski avtomatizaciji.

2. Katere so ključne komponente, ki se uporabljajo v PCBA?

Ključne komponente so upori, kondenzatorji, diode, tranzistorji, integrirana vezja (IC), konektorji in induktorji.

3. Katere metode testiranja se uporabljajo pri PCBA?

Običajne metode testiranja vključujejo testiranje v vezju (ICT), funkcionalno testiranje (FCT), samodejni optični pregled (AOI) in rentgensko pregledovanje.

4. Kateri so izzivi pri izdelavi PCBA?

Izzivi vključujejo zagotavljanje zanesljivosti spajkanja, upravljanje velike gostote komponent, zmanjševanje elektromagnetnih motenj (EMI) in doseganje natančne namestitve komponent.