Technické parametre PCB a PCBA

| Položka | Schopnosti |

|---|---|

| Štandard kvality | Štandard IPC 2 |

| Vrstvy | 1-32 vrstiev |

| Suroviny | ▪FR4 ▪CEM3 ▪Rogers ▪Teflon ▪Kovové |

| Maximálna veľkosť | ▪850mm*520mm |

| Min. priemer vŕtania | 0,15 mm |

| Hrúbka medi | 0,25OZ-15OZ |

| Tolerancia impedancie | ±5% |

| Povrchová úprava | ▪Bezolovnatý HASL ▪OSP ▪ENIG ▪Zlatenie ▪Immersion Ag/Sn |

| Položka | Schopnosti |

|---|---|

| Štandard kvality | IPC-610-C |

| Montážna technológia | ▪SMT šablóna ▪SMT ▪DIP ▪Konformný povlak |

| Certifikácia podnikov | ▪ISO9001 ▪IATF16949 ▪ISO13485 ISO14001 |

| Certifikácia produktu | ▪UL ▪RoHS ▪SGS ▪REACH |

| Schopnosť SMD | ▪Minimálna veľkosť: 01005 ▪BGA0,2 mm, QFN, CSP, CON ▪Maximálna veľkosť PCB: 510*460 mm |

| Funkcie s pridanou hodnotou | ▪Obstarávanie komponentov ▪NPI správa ▪PCBA prototyp ▪IC programovanie ▪Oprava |

| Proces testovania | ▪AOI ▪Röntgen ▪SPI ▪FAI ▪FCT ▪ICT ▪Test starnutia ▪QC Manuálna detekcia |

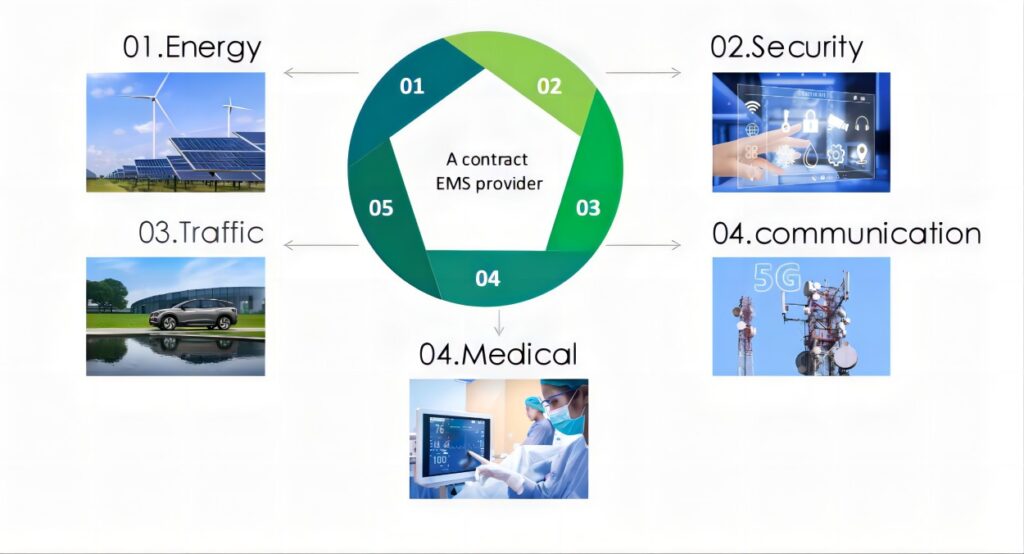

Oblasti použitia PCBA,Špecifické aplikácie PCBA,O nás,Služby PCBA,Bezpečnosť,Systém,Komunikácia,Zariadenie,Bez vodiča,Nový energetický systém,Zdravotnícke zariadenie,Často kladené otázky o aplikáciách PCB a PCBA,1. Aké odvetvia používajú aplikácie PCBA?,Aplikácie PCBA zahŕňajú spotrebnú elektroniku, automobilový priemysel, letecký priemysel, zdravotnícke zariadenia, telekomunikácie a priemyselnú automatizáciu,2. Aké sú kľúčové komponenty používané v PCBA?,Medzi kľúčové komponenty patria rezistory, kondenzátory, diódy, tranzistory, integrované obvody (IC), konektory a induktory.,3. Aké testovacie metódy sa používajú v PCBA?,Medzi bežné testovacie metódy patrí testovanie v obvode (ICT), funkčné testovanie (FCT), automatizovaná optická kontrola (AOI) a röntgenová kontrola,4. Aké sú výzvy pri výrobe PCBA?, Medzi výzvy patrí zabezpečenie spoľahlivosti spájkovaných spojov, zvládnutie vysokej hustoty komponentov, minimalizácia elektromagnetického rušenia (EMI) a dosiahnutie presného umiestnenia komponentov., Bezpečnostný systém, Komunikačné zariadenie, Systém bez vodiča, Nový energetický systém.

Specific applications of PCBA

Security System

Communication Device

Driverless System

New Energy System

Medical Device

FAQ of PCB and PCBA Applications

1. What industries use PCBA applications?

PCBA applications include consumer electronics, automotive, aerospace, medical devices, telecommunications, and industrial automation.

2. What are the key components used in PCBA?

Key components include resistors, capacitors, diodes, transistors, integrated circuits (ICs), connectors, and inductors.

3. What testing methods are used in PCBA?

Common testing methods include In-Circuit Testing (ICT), Functional Testing (FCT), Automated Optical Inspection (AOI), and X-ray inspection.

4. What are the challenges in PCBA manufacturing?

Challenges include ensuring solder joint reliability, managing high component density, minimizing electromagnetic interference (EMI), and achieving precise component placement.