Introduction

The journey from concept to finished product in the electronics industry hinges on the precision and efficiency of the PCB (Printed Circuit Board) manufacturing process. This intricate process involves multiple stages, each crucial to ensuring the final product meets stringent standards and performs reliably. From initial design to final delivery, every step plays a vital role in the creation of high-quality electronic devices.

Design Phase

Creating the Digital Blueprint

The PCB manufacturing process begins with the design phase, where engineers use specialized software to develop a detailed digital blueprint of the PCB. This design process must account for various factors, including the type of components, board layout, and electrical connections. After completing the initial design, it undergoes rigorous reviews and refinements to ensure it adheres to required specifications and standards.

Fabrication

From Design to Physical Board

Once the design is finalized, the next step is fabricating the physical PCB. This involves etching copper layers on the board through a chemical process and drilling holes for component placement. The board is then plated with a thin layer of copper to create a surface for soldering components.

Component Placement

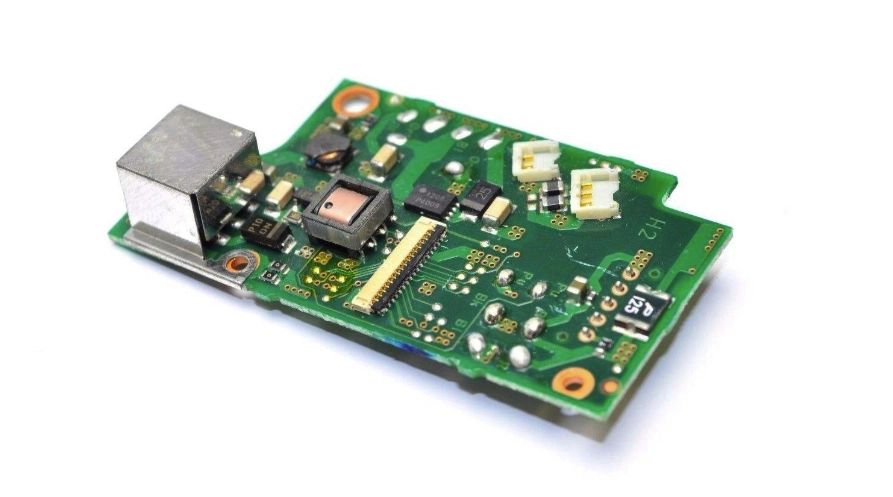

Assembling with Surface Mount Technology

With the PCB prepared, components are placed onto the board using Surface Mount Technology (SMT). This process involves positioning components accurately and soldering them in place using heat and pressure. Proper alignment and placement are critical to ensure reliable electrical connections and functionality.

Testing and Inspection

Ensuring Quality and Reliability

After component placement, the PCB undergoes extensive testing and inspection to verify it meets required standards. This includes visual inspections, electrical testing, and environmental testing to assess the board’s durability under real-world conditions. These tests help identify any defects and ensure the board’s reliability.

Final Assembly and Delivery

From PCB to Complete Device

Following successful testing, the PCB is assembled into a complete electronic device. This may involve integrating additional components like connectors, switches, and buttons, and installing the PCB into a housing. The final product is then packaged and shipped to customers.

Technological Advancements

Enhancing Efficiency and Quality

Technology plays a crucial role throughout the PCB manufacturing process. Advances in design software, automated machinery for etching and drilling, and specialized testing equipment have significantly improved the quality, efficiency, and cost-effectiveness of PCB production. These advancements enable manufacturers to produce high-quality PCBs faster and with greater reliability.

Quality Control and Supply Chain Management

Ensuring Standards and Timely Delivery

Effective quality control and supply chain management are essential for maintaining product standards and ensuring timely delivery. Manufacturers must carefully plan, coordinate, and communicate throughout the manufacturing process to meet deadlines and fulfill orders accurately.

Conclusion

The PCB manufacturing process is a detailed and precise journey from design to delivery. Each stage, from initial design and fabrication to component placement, testing, and final assembly, is crucial for producing reliable and high-quality electronic devices. Technological advancements continue to enhance the efficiency and reliability of PCB production, meeting the growing demands of the electronics industry. As the need for sophisticated electronic devices increases, the importance of a well-executed PCB manufacturing process will continue to grow.

FAQs

Q: What are the initial steps in the PCB manufacturing process?

A: The process begins with the design phase, where a digital blueprint of the PCB is created using specialized software. This is followed by fabricating the physical board through etching and plating.

Q: How are components added to the PCB?

A: Components are added using Surface Mount Technology (SMT), which involves placing components on the board and soldering them in place with heat and pressure.

Q: What tests are performed on the PCB before final assembly?

A: The PCB undergoes visual inspections, electrical testing, and environmental testing to ensure it meets required standards and performs reliably.

Q: How does technology impact PCB manufacturing?

A: Technology enhances efficiency and quality through advanced design software, automated machinery, and specialized testing equipment, leading to faster production and higher reliability.

Q: What is crucial for ensuring timely delivery of PCBs?

A: Effective quality control and supply chain management are essential for meeting standards and delivering products on time. This involves careful planning and coordination throughout the manufacturing process.