Importance of DFM in PCBA Ensuring Cost-Effective and Reliable Production DFM plays a crucial role in PCBA design by addressing various manufacturing constraints like component placement, routing, and assembly processes during the design phase. This foresight helps prevent costly rework, reduce waste, and enhance product reliability. For example, a design that simplifies the assembly process […]

Author Archives: admin

Identifying PCBA Requirements Understanding Application Needs and Specifications The initial phase of component selection involves identifying the specific requirements of the PCBA. This includes understanding the application type, operating conditions, and performance specifications. For instance, a PCBA meant for a high-reliability application might need components with an extended lifespan and a higher tolerance to environmental […]

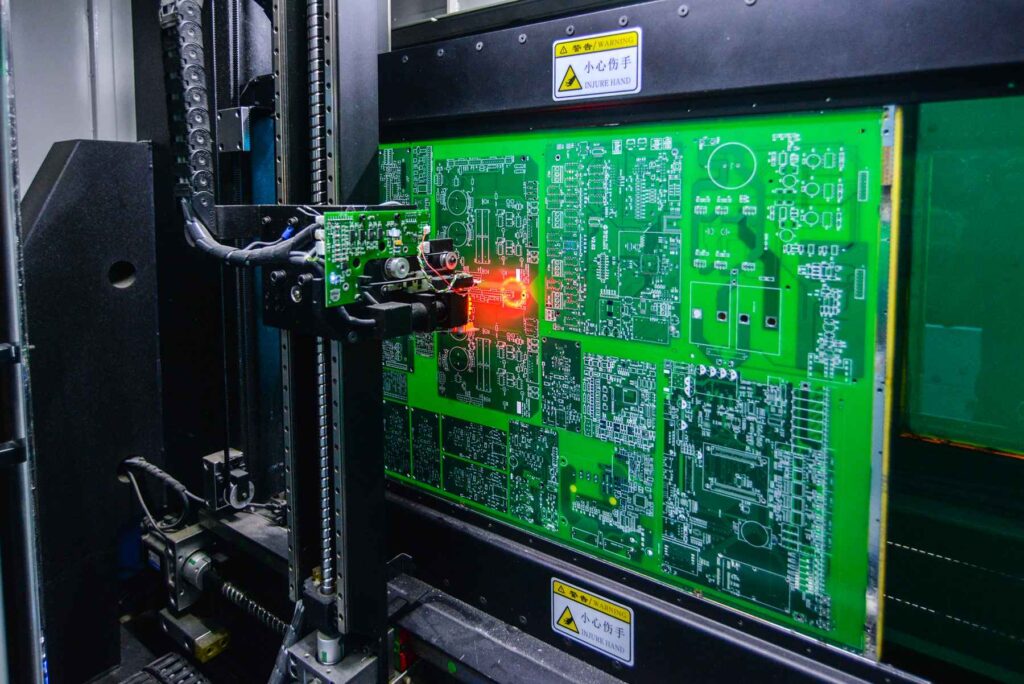

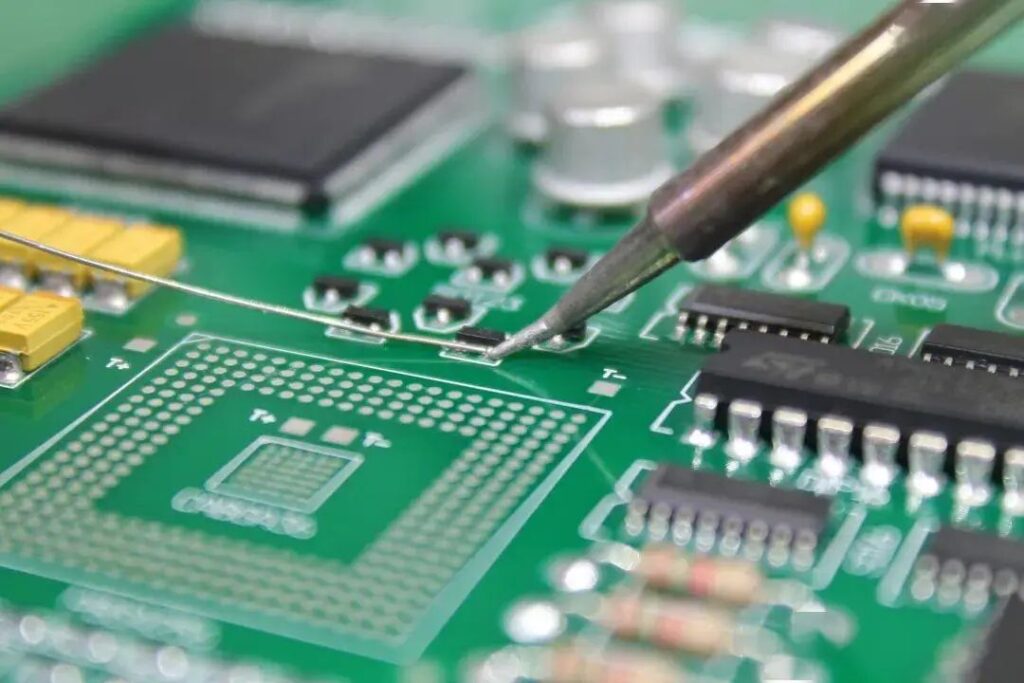

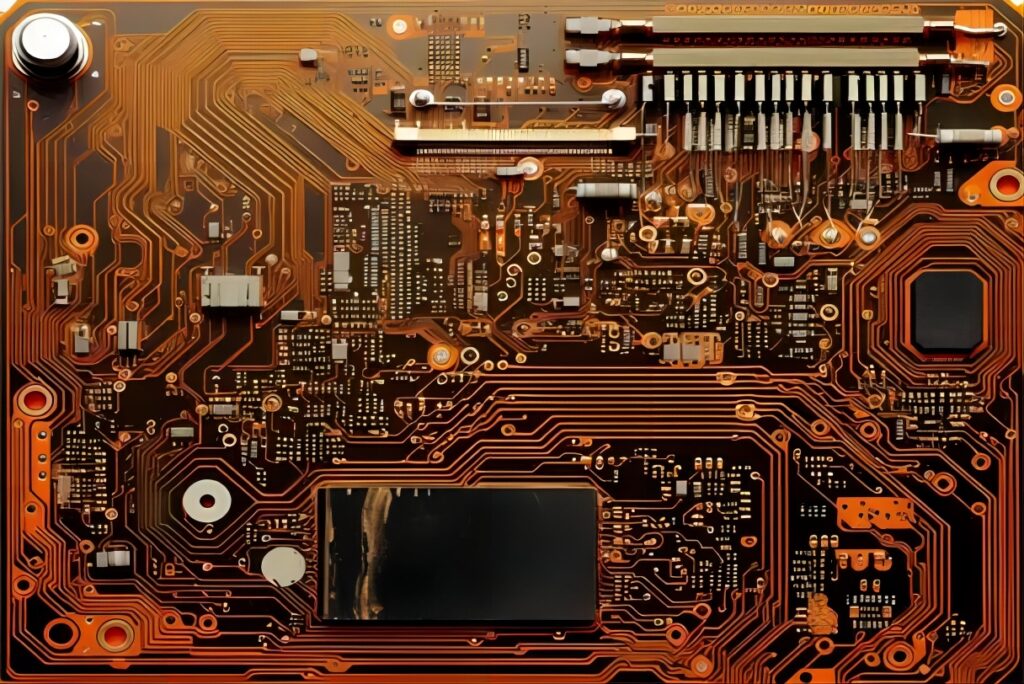

Preparing the Printed Circuit Board Ensuring a Clean and Defined Surface The initial phase of the assembly process involves preparing the printed circuit board. The board is thoroughly cleaned to eliminate any dirt or debris that could interfere with the assembly process. A solder mask is then applied to the board to protect it from […]

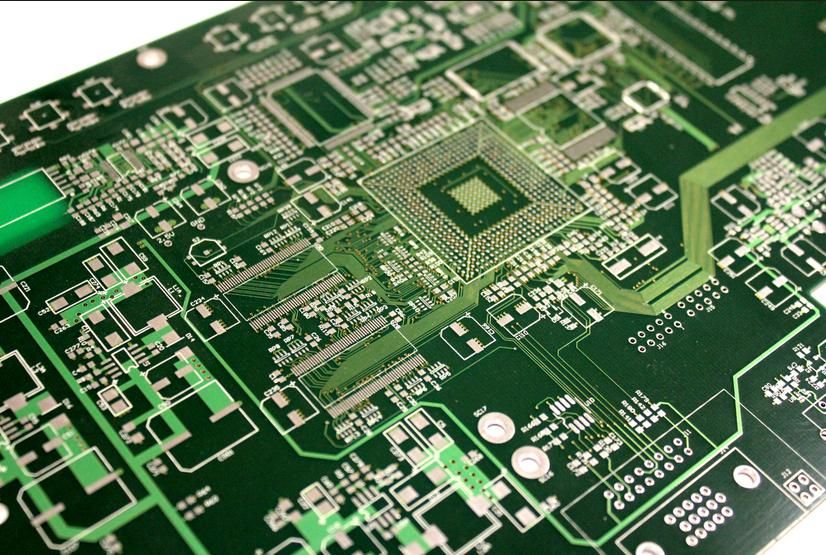

Understanding the Manufacturing Process Gaining Insight into Production Capabilities The foundation of successful PCB design for manufacturability lies in a thorough understanding of the manufacturing process and the capabilities of the manufacturing facility. This includes knowledge of the types of materials and technologies used, as well as the limitations and constraints of the manufacturing process. […]

Determining the Testing Requirements Identifying the Appropriate Testing Methods The first step in PCB testing is determining the type of testing required. This depends on the PCB’s type, intended application, and the level of quality control needed. Testing methods include visual inspection, electrical testing, and functional testing. Visual inspection checks for defects like cracks, scratches, […]

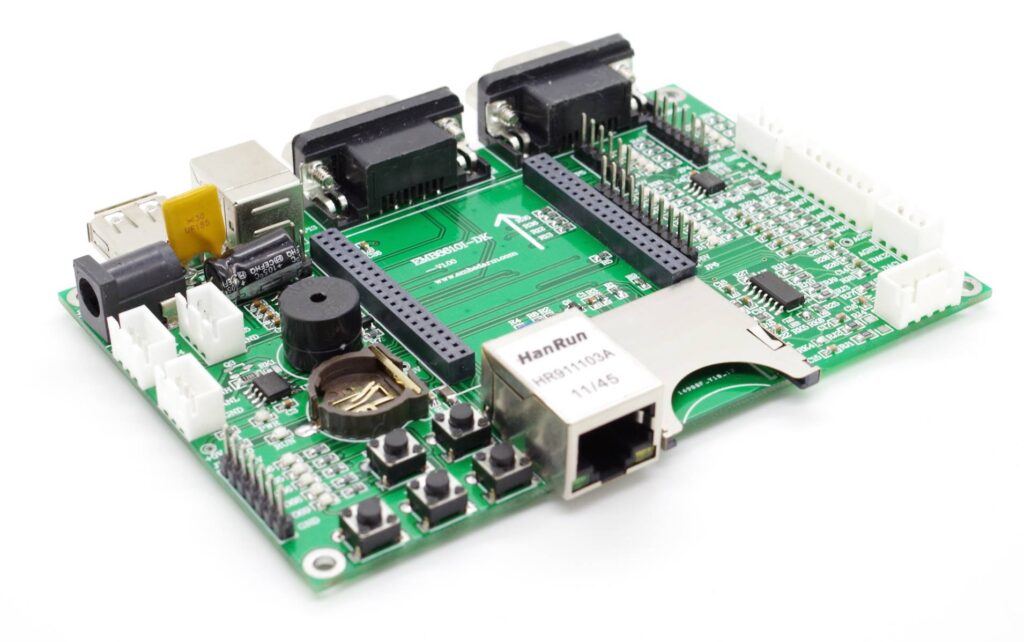

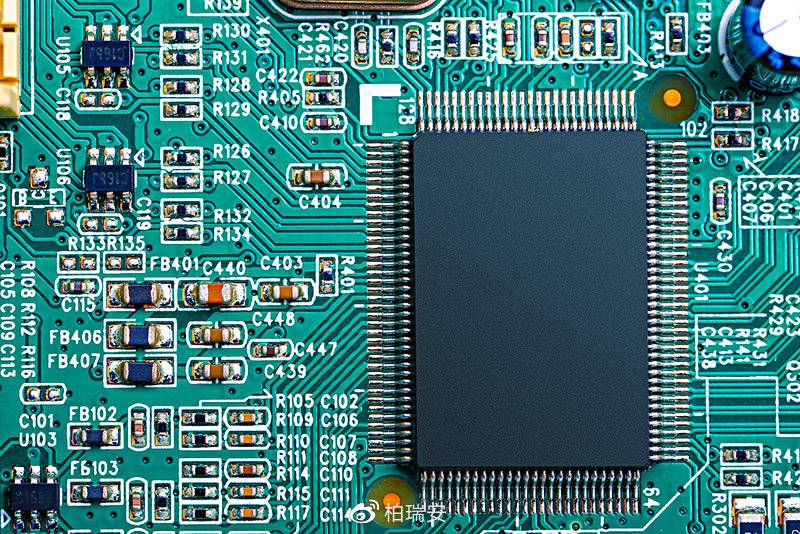

Component Placement Precision in Positioning The first step in PCB assembly is the placement of components onto the board. This process involves accurately positioning each component, such as resistors, capacitors, and integrated circuits, on the board’s surface. Both manual and automated techniques are employed, with automated placement machines becoming increasingly prevalent in modern manufacturing. These […]

Design Phase Blueprint Creation and Prototyping The PCB manufacturing journey begins with the design phase, where engineers and designers create a detailed blueprint. This blueprint considers various factors, including component placement, wiring, and layer thickness. After the blueprint is completed, a physical prototype is developed and tested to ensure it meets the necessary specifications. The […]

Common PCB Materials FR4 – A Popular Choice The most prevalent material used in PCB construction is FR4, a fiberglass-reinforced epoxy laminate. Renowned for its high thermal stability, mechanical strength, and resistance to moisture and chemicals, FR4 is widely utilized in consumer electronics, automotive, and industrial control systems. Despite its popularity, FR4 presents limitations like […]

Material Selection The choice of materials is a crucial aspect of PCB design that directly impacts the performance and reliability of the final product. Key considerations include the substrate, copper thickness, and solder mask. A substrate with high thermal conductivity aids in dissipating heat generated by components, while inadequate copper thickness can compromise the board’s […]

What is PCBA? PCBA stands for Printed Circuit Board Assembly, which involves the process of mounting electronic components onto a printed circuit board (PCB). The PCB provides the foundation and interconnections for the components, enabling them to function as a cohesive unit. PCBA is essential in the creation of various electronic devices, from simple household […]