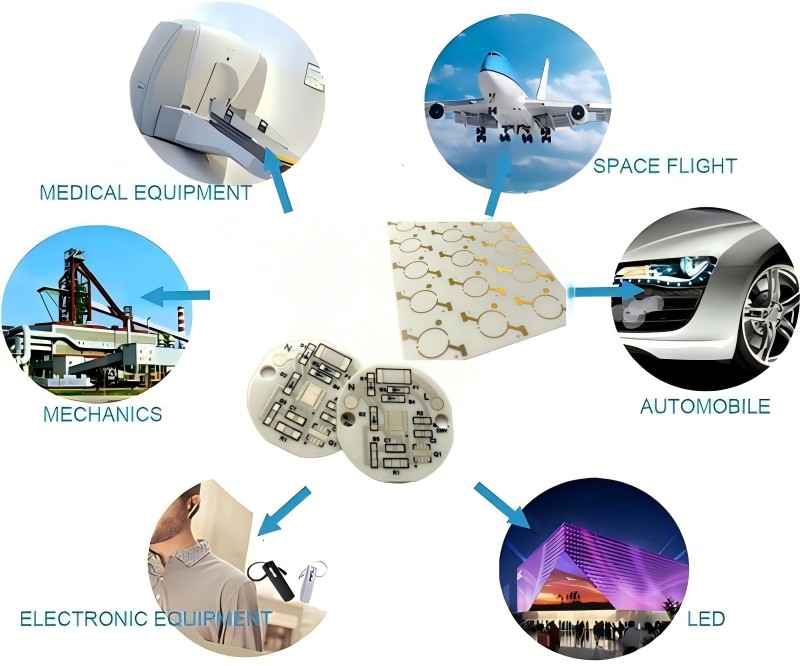

Ceramic PCB: A High-Performance Solution

Ceramic PCBs are a specialized type of printed circuit board (PCB) substrate made from ceramic materials, such as alumina or beryllia. These boards offer superior performance and reliability compared to traditional FR-4 (flame-retardant epoxy resin) boards, making them ideal for applications requiring high thermal conductivity, low dielectric loss, and excellent mechanical strength.

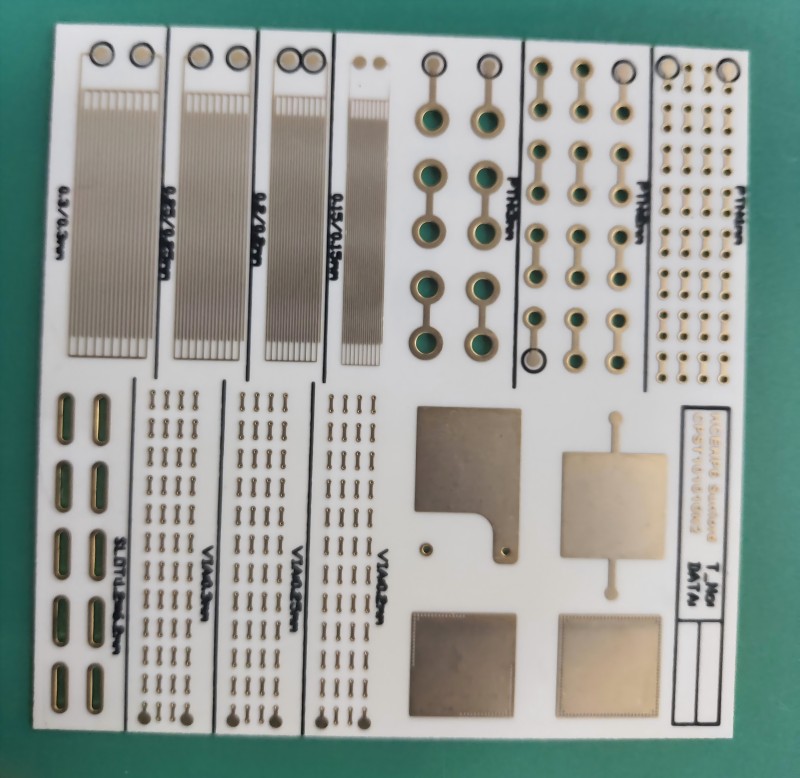

Key Features of Ceramic PCB:

- High Thermal Conductivity: Ceramic materials have excellent thermal conductivity, allowing for efficient heat dissipation and preventing overheating of electronic components.

- Low Dielectric Loss: Ceramic circuit boards exhibit low dielectric loss, ensuring minimal signal distortion and high-frequency performance.

- Excellent Mechanical Strength: Ceramic boards are highly durable and resistant to physical stress, making them suitable for demanding applications.

- High-Temperature Resistance: Ceramic materials can withstand high temperatures, making them ideal for applications in harsh environments.

- Dimensional Stability: Ceramic boards have excellent dimensional stability, ensuring precise placement of components and reliable electrical connections.