Introduction of PCBA Manufacturing

PCBA manufacturing, or Printed Circuit Board Assembly manufacturing, is a vital process in the electronics industry. It involves assembling various electronic components onto a printed circuit board (PCB), transforming it into a fully functional electronic device. This complex process requires a high level of precision, expertise, and knowledge of electronic components and their functions. As technology advances, the demand for high-quality PCBAs is expected to grow, making this manufacturing process more critical than ever.

The Foundation: PCB Design and Layout

The first step in PCBA manufacturing is the design and layout of the PCB. This stage is crucial as it determines the placement of electronic components and the routing of electrical connections. A meticulously planned design ensures the final product will function efficiently and effectively. Once the design is finalized, the PCB is fabricated by etching the circuit pattern onto a copper-clad board, drilling holes for component leads, and applying a solder mask to protect the copper traces.

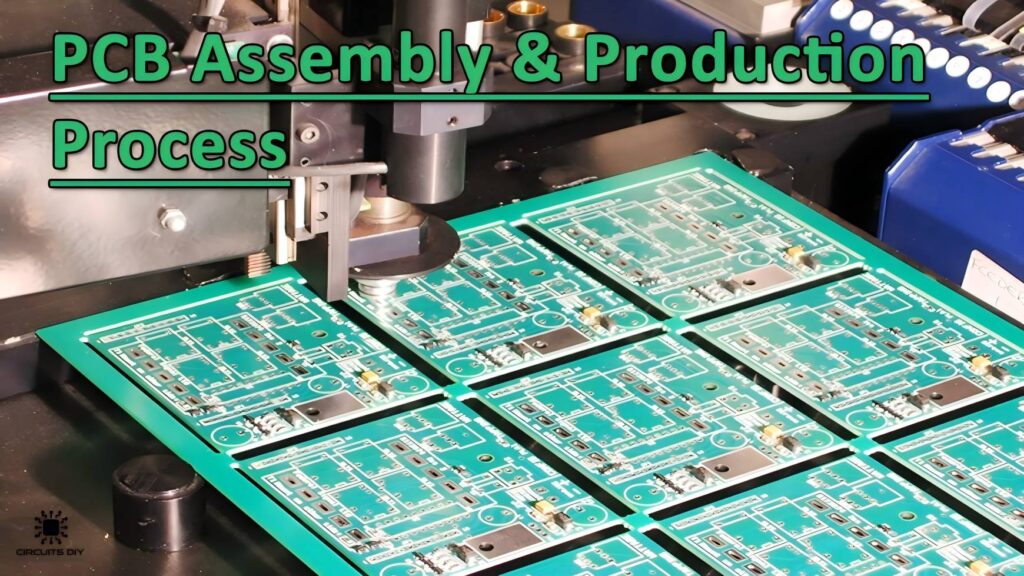

Assembly Process: Bringing the PCB to Life

After the PCB is fabricated, the assembly of electronic components begins, marking the start of the PCBA process. This stage involves the precise placement of components onto the PCB and their subsequent soldering. Depending on the production volume and complexity, this can be done manually or through automated machines. Proper component placement and secure soldering are critical for the functionality and durability of the final product.

Component Selection: Ensuring Quality and Compatibility

The selection of electronic components is another key aspect of PCBA manufacturing. Components like resistors, capacitors, integrated circuits, and connectors must be carefully chosen to meet the specifications of the final product. The quality and reliability of these components are paramount, as they directly influence the performance of the electronic device.

Testing and Inspection: Guaranteeing Performance

Testing and inspection are essential to ensure that the assembled PCB functions as intended. Various tests, including visual inspection, automated optical inspection, and in-circuit testing, are conducted to identify any defects or issues. These rigorous checks are vital to maintaining the high standards required in electronic device manufacturing.

Conclusion of PCBA Manufacturing

PCBA manufacturing is a specialized field that plays a critical role in the electronics industry. From designing the PCB layout to selecting components and performing rigorous testing, every step in the process is crucial to ensuring the final product’s efficiency and reliability. As technology continues to evolve, the importance of PCBA manufacturing will only increase, underscoring its essential role in producing high-quality electronic devices.

PCBA Manufacturing FAQ

Q1: What does PCBA stand for?

A1: PCBA stands for Printed Circuit Board Assembly, which is the process of assembling electronic components onto a printed circuit board (PCB).

Q2: What is the first step in PCBA manufacturing?

A2: The first step is the design and layout of the PCB, where the placement of components and routing of electrical connections are meticulously planned.

Q3: How is the PCB fabricated?

A3: The PCB is fabricated by etching the circuit pattern onto a copper-clad board, drilling holes for component leads, and applying a solder mask to protect the copper traces.

Q4: What happens during the assembly process?

A4: During assembly, electronic components are precisely placed onto the PCB and soldered into place, which can be done manually or with automated machines.

Q5: How important is the selection of electronic components?

A5: The selection is crucial as components like resistors, capacitors, and integrated circuits must meet the product’s specifications to ensure quality and performance.

Q6: What types of testing are conducted in PCBA manufacturing?

A6: Various tests, including visual inspection, automated optical inspection, and in-circuit testing, are performed to ensure the PCB functions as intended and meets quality standards.

Q7: Why is PCBA manufacturing important?

A7: PCBA manufacturing is essential because it ensures that electronic devices function efficiently and reliably, making it a critical process in the electronics industry.