What Injection Molding Product Services can UTC Provide?

Injection Molding Product Moulding Development and Design

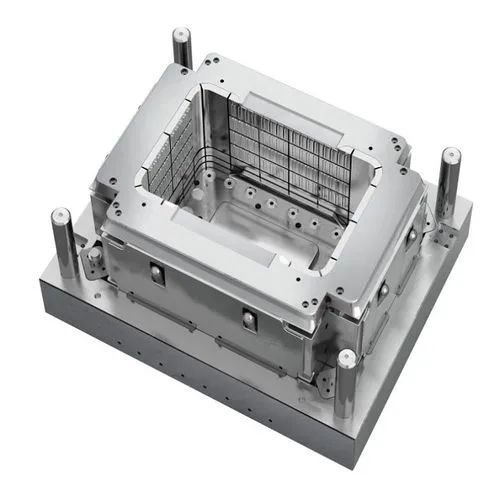

Mold development and design encompass the intricate process of crafting molds that transform molten materials into precise and functional products. This meticulous process involves:

Conceptualizing and designing molds: Utilizing CAD software and engineering expertise to create detailed mold designs that meet product specifications.

Material selection: Selecting appropriate mold materials that can withstand the manufacturing process and impart the desired properties to the final product.

Mold fabrication: Employing precision machining techniques to manufacture molds with exacting tolerances and surface finishes.

Testing and refinement: Rigorously testing molds to ensure they produce high-quality products and making adjustments as needed.

Injection Molding Product Molding

Injection plastic molding is a manufacturing process that transforms molten plastic into a vast array of products, from intricate components to everyday household items. This versatile technique is renowned for its efficiency, precision, and ability to produce complex shapes in high volumes.

Plastic Preparation: Plastic pellets or granules are heated to a molten state, ready for injection.

Plastic Molding: The molten plastic is injected under high pressure into a precisely crafted mold, replicating the desired product shape.

Cooling and Solidification: The plastic cools within the mold, solidifying into the final product form.

Ejection: Once solidified, the finished product is ejected from the mold.

Repetition: The cycle repeats continuously, enabling high-volume production.

Full Product Inspection and Packaging

Full product inspection and packaging are crucial steps in the manufacturing process, guaranteeing product quality and safeguarding them during transportation.

Full Product Inspection:

Thorough Examination: Each product undergoes a comprehensive check for defects, ensuring it meets specifications and quality standards.

Visual Inspection: Appearance, completeness, dimensions, and labeling are meticulously evaluated.

Functional Testing: Products are tested to ensure they operate as intended.

Packaging:

Protective Materials: Appropriate packaging materials are selected to protect products from damage during transit.

Proper Packing: Products are carefully packed to prevent movement and jostling within the packaging.

Clear Labeling: Clear and accurate labeling provides essential information for identification and handling.

Various Injection Molding Product

Frequently Asked Questions About Injection Molding Product

Plastic moulding is a highly versatile manufacturing process used to create a wide range of products across various industries. Here are some examples:

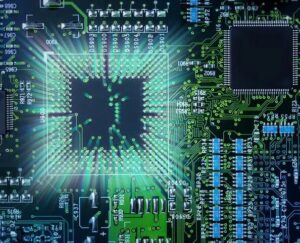

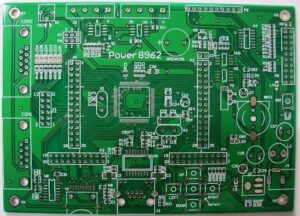

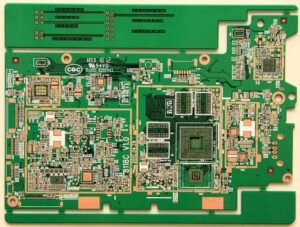

- Electronic components (housings, casings, connectors)

- Consumer goods (toys, appliances, furniture components)

- Automotive parts (interior trim, dashboards, bumpers)

- Medical devices (syringes, housings, sterilization trays)

- Packaging (bottles, containers, closures)

Injection molding can be used to produce a wide variety of products, including automotive parts, consumer electronics, toys, medical devices, and household goods.

Design considerations include:

- Part complexity

- Material selection

- Mold design

- Tolerances

- Cost analysis

Using recycled plastic offers several advantages:

- Environmental Sustainability: Reduces reliance on virgin plastic materials and minimizes landfill waste.

- Cost Savings: Recycled plastic can be a more cost-effective option compared to virgin materials.

- Performance: Many recycled plastics offer similar performance characteristics to virgin materials

Consider these factors when selecting a plastic molding company:

- Experience & Expertise: Look for a company with experience in producing similar parts to yours.

- Capabilities & Technologies: Ensure they have the necessary technology and equipment for your chosen molding technique.

- Quality Control & Standards: Ask about their quality control processes and certifications.

- Communication & Customer Service: Choose a company that offers clear communication and responsive customer support.